PVC stabilizer wax

Category:

Keywords:

PVC stabilizer wax

- Details

-

Technical Indicators

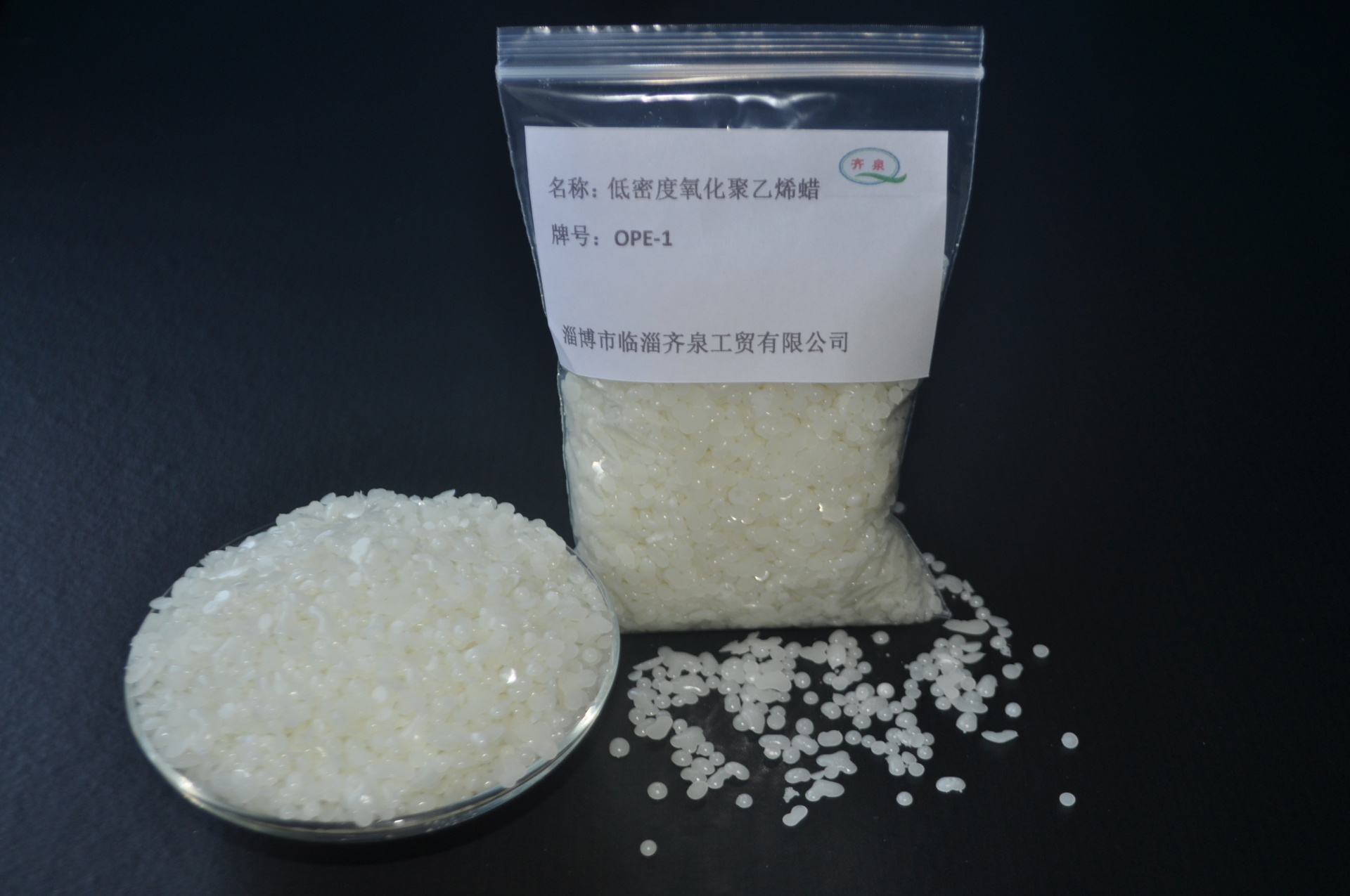

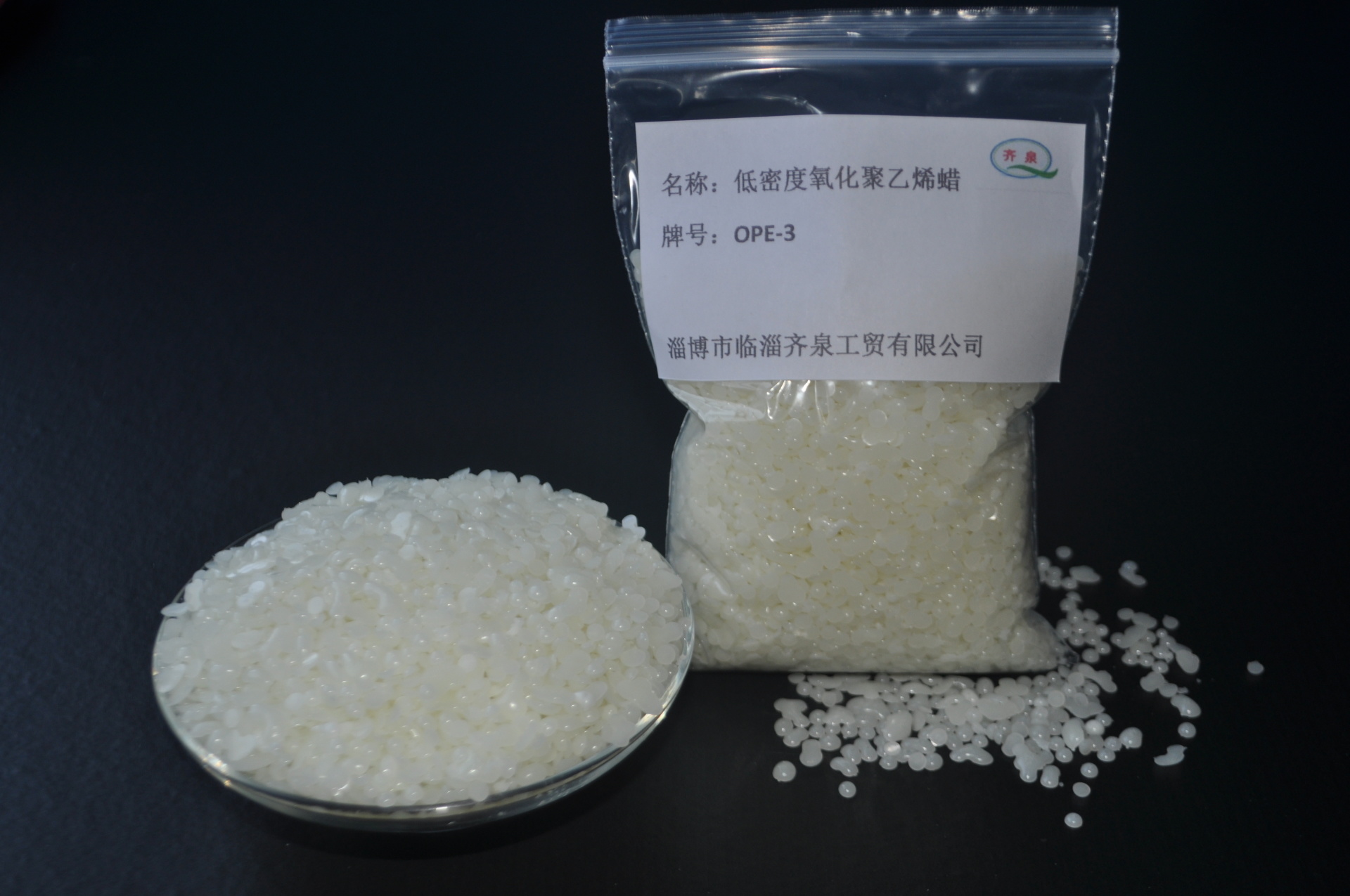

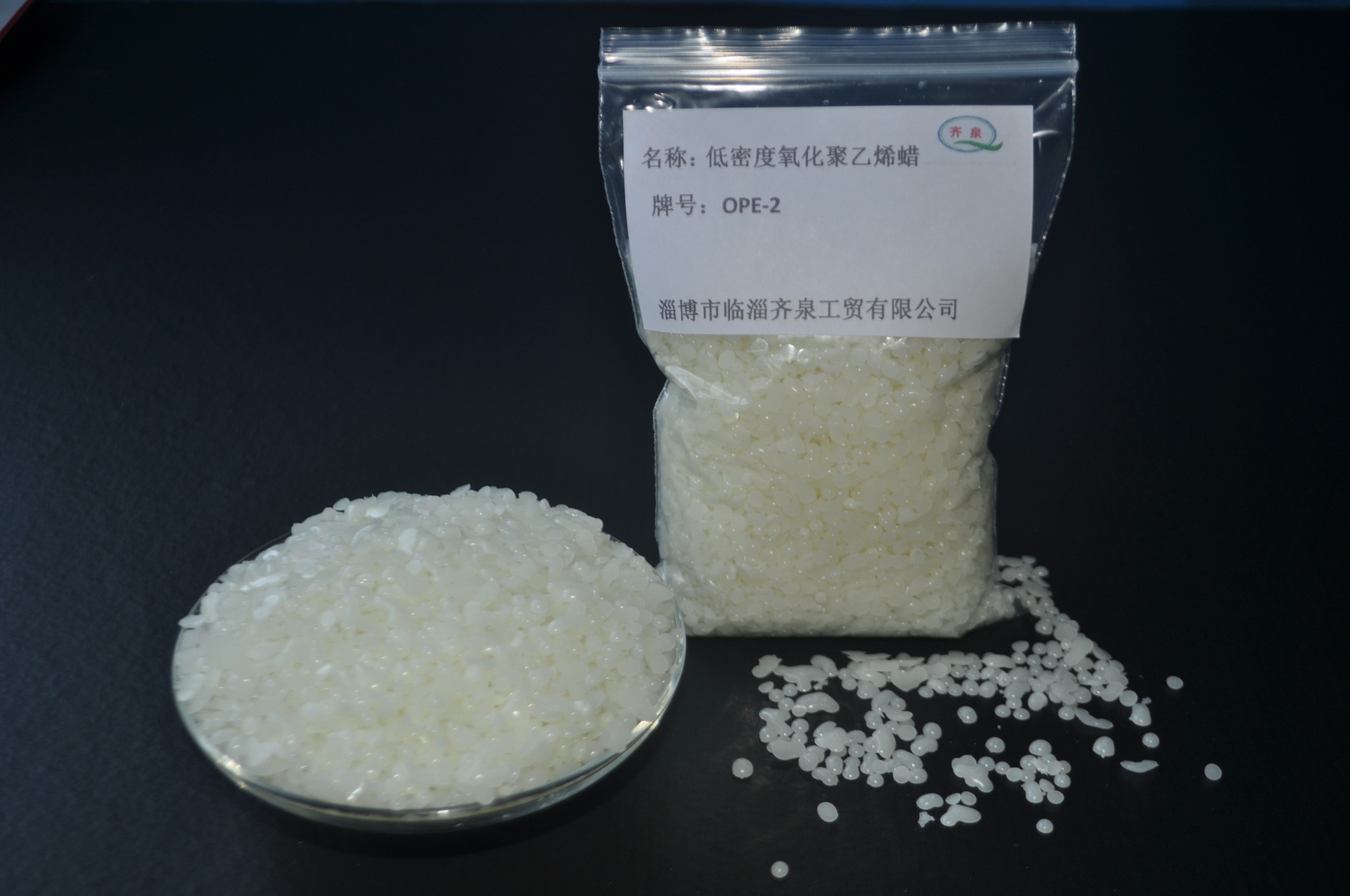

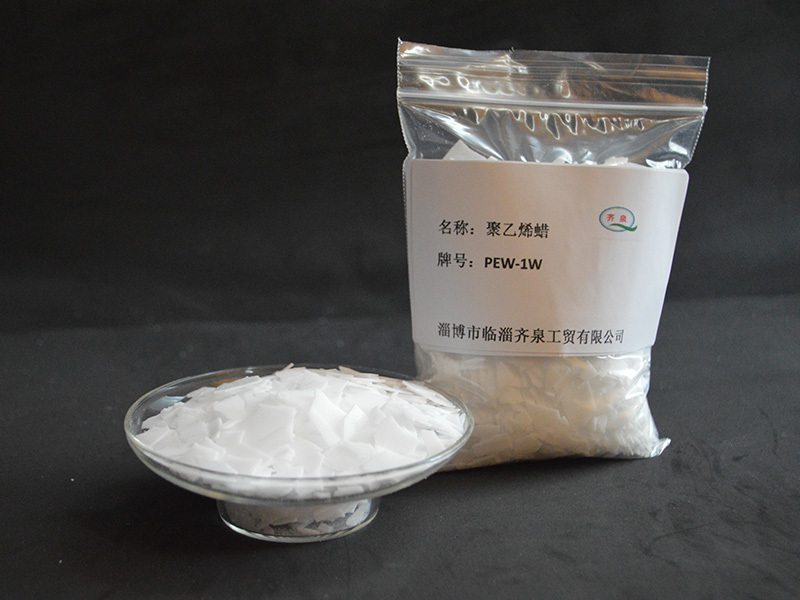

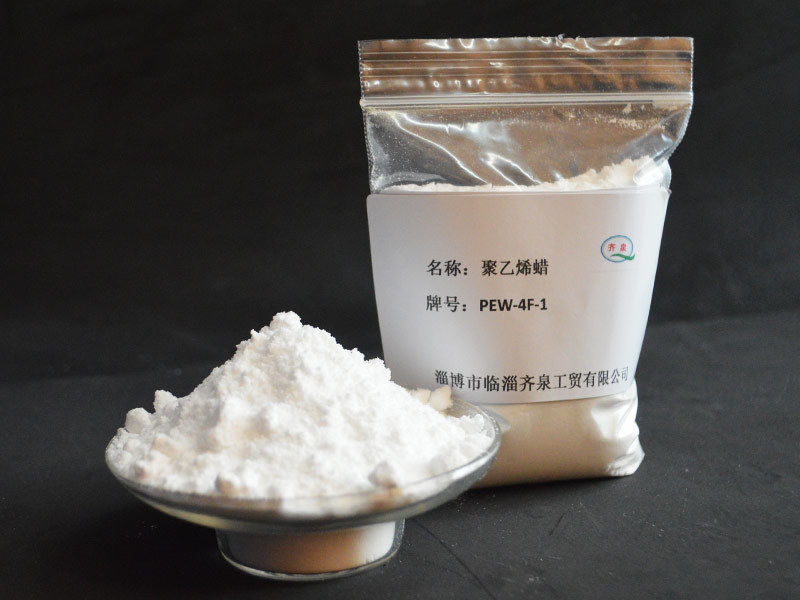

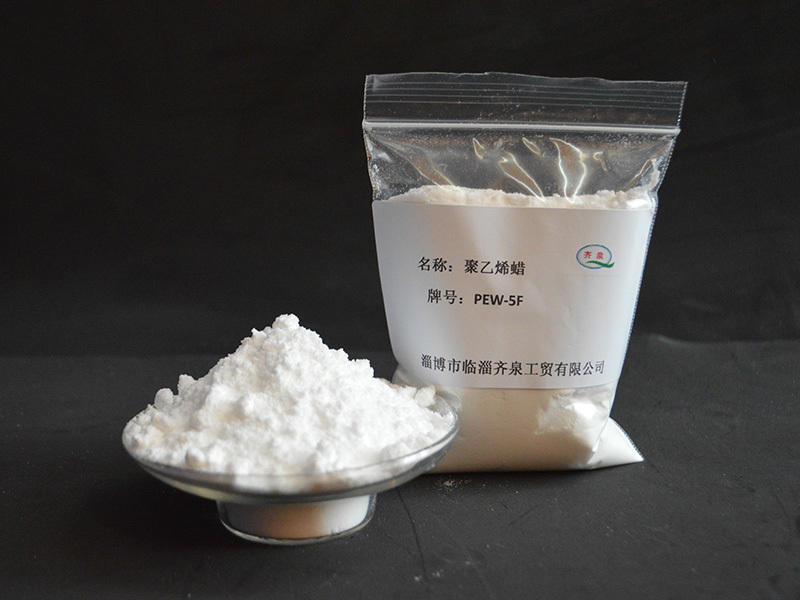

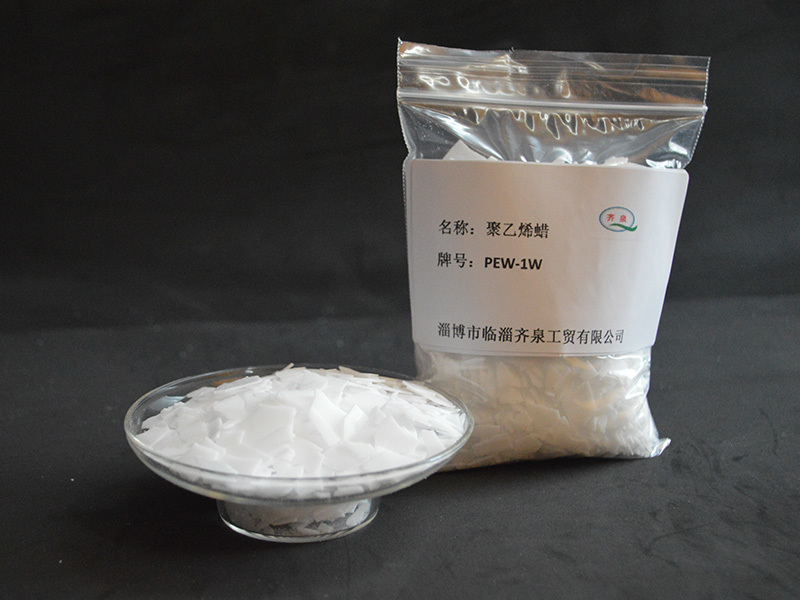

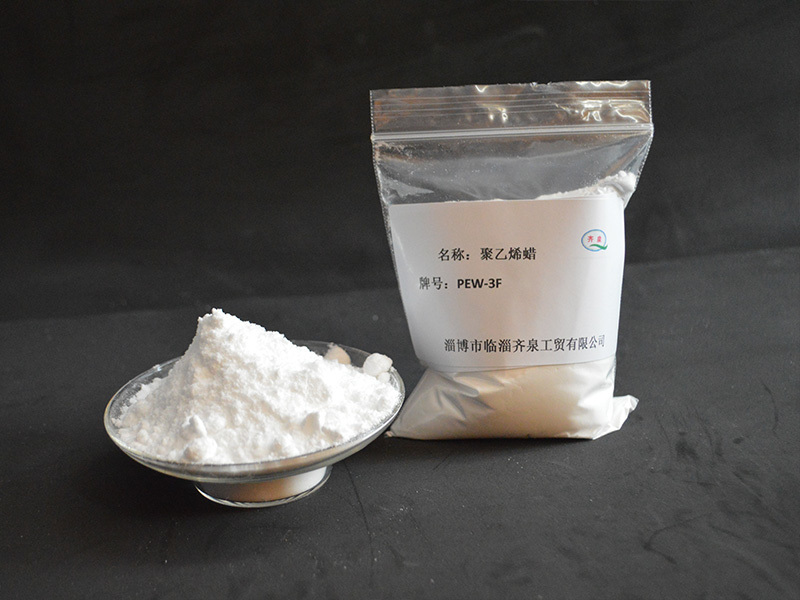

Product Indicators PEW-5F PEW-1W PEW-8W Molecular Weight 3000-5000 2000-3000 2000-2500 Melting Point (°C) 115℃ 105℃ 105℃ Density (g/cm3) 0.95 0.93 0.93 Appearance White powder White granules/flakes White powder Product Advantages

1. High softening point, low viscosity, high molecular weight, and low heat loss.

2. Strong external lubrication; compared with ordinary polyethylene wax, it can better delay plasticization and reduce torque.

3. Easy to disperse and can improve the gloss of the product.

4. Good compatibility and anti-separation.

5. Good demolding properties, good metal peelability, and long continuous production time.

6. Good later thermal stability; does not contain oligomers, paraffin, etc. No separation or migration.

7. Environmentally friendly and passes ROHS and heavy metal tests.

Product Applications

1. Calcium-zinc stabilizer

2. Lead salt stabilizer

Packaging and Storage

Plastic woven bag, net weight: 25 kg/bag. Please pre-order for special packaging.

This product is non-hazardous. Please keep away from fire, high temperatures, humidity, and strong oxidants.

Product Inquiry

Filling in your phone number and E-mail information will help us contact you promptly and quickly resolve the issues you raise.

Related Products

High-performance Ceramic Precursors

Liquid Polycarbosilane

-

Liquid polycarbosilane (ZQ-C20)

This product is a solvent-free, low-viscosity liquid organosilicon polymer. Its molecular structure contains crosslinkable active groups such as Si-H and allyl groups, which can be crosslinked and cured under mild conditions. Pyrolysis of the cured product under an inert atmosphere can be converted into silicon carbide ceramics with high yield.

-

Liquid polycarbosilane (ZQ-C30)

This product is a low-viscosity liquid organosilicon polymer. Its molecular structure contains crosslinkable active groups such as Si-H and allyl groups, which can be crosslinked and cured under mild conditions. It has low volatile content, does not produce gas or foam during curing, and the cured product can be converted into carbon-rich silicon carbide ceramics with high yield by pyrolysis under an inert atmosphere.

-

Liquid polycarbosilane (ZQ-V20)

This product is a low-viscosity liquid organosilicon polymer. Its molecular structure contains crosslinkable active groups such as Si-H and vinyl, which can be crosslinked and cured under mild conditions. It has low volatile content, does not produce gas or foam during curing, and the cured product can be converted into silicon carbide ceramics with a near-stoichiometric ratio of SiC with high yield by pyrolysis under an inert atmosphere.

Liquid Polysilazane

-

Liquid polysilazane (ZQ-N50K)

Polysilazane is an organic-inorganic hybrid polymer with Si-N bonds as its main chain. It possesses good chemical activity and structural adjustability. It can be used as a precursor resin for SiCN ceramic matrix composites, a high-temperature adhesive, and a base polymer for ceramic coatings. It can also be used as a thermosetting resin, a modifying agent or cross-linking agent for other polymers.

-

Liquid polysilazane (ZQ-N50)

Polysilazane is an organic-inorganic hybrid polymer with Si-N bonds as the main chain. It has good chemical activity and structural adjustability. It can be used as a precursor resin for ceramic matrix composites such as SiCN, a high-temperature adhesive, and a base polymer for ceramic coatings. It can also be used as a thermosetting resin, a modifying agent or crosslinking agent for other polymers.

-

Liquid polysilazane (ZQ-N2K)

Polysilazane is an organic-inorganic hybrid polymer with Si-N bonds as the main chain. It has good chemical activity and structural adjustability. It can be used as a precursor resin for ceramic matrix composites such as SiCN, a high-temperature adhesive, and a base polymer for ceramic coatings. It can also be used as a thermosetting resin, a modifying agent or crosslinking agent for other polymers.

-

Liquid polysilazane (ZQ-N200)

Polysilazane is an organic-inorganic hybrid polymer with Si-N bonds as its main chain. It possesses good chemical activity and structural adjustability. It can be used as a precursor resin for ceramic matrix composites, a high-temperature adhesive, and a base polymer for ceramic coatings. It can also be used as a thermosetting resin, a modifying agent for other polymers, or a cross-linking agent.

Liquid Polyborosilazane

-

Liquid polyborosilazane (ZQ-B10)

This product is a solvent-free liquid silicon boron hybrid polymer that can be used as a precursor resin for SiBCN ceramic matrix composites, and can also be used as a modifying agent for thermosetting resins and other polymers.

-

Liquid polyborosilazane (ZQ-B100)

This product is a solvent-free liquid silicon-boron hybrid polymer. Its molecular structure contains crosslinkable active groups such as vinyl groups, which allow for crosslinking and curing under mild conditions. The cured product can be converted into silicon boron carbon nitride (SiBCN) ceramic by pyrolysis under an inert atmosphere, and into silicon boron nitride (SiBN) ceramic by pyrolysis under ammonia.

-

Liquid polyborosilazane (ZQ-B400)

This product is a solvent-free liquid silicon-boron hybrid polymer. Its molecular structure contains crosslinkable active groups such as vinyl groups, and it can be crosslinked and cured under relatively mild conditions. Pyrolysis of the cured product under an inert atmosphere can convert it into silicon boron carbon nitride (SiBCN) ceramic, while pyrolysis under ammonia can convert it into silicon boron nitride (SiBN) ceramic.

Wax Fine Chemicals

High-Density Oxidized Polyethylene Wax

-

Wax emulsion

-

Modified asphalt

-

PVC profile pipe

-

PVC stabilizer

-

PVC transparent products

-

PVC edge banding

-

PVC foam products

-

CPVC

-

QHO-6316

-

PVC foam products

PVC foam products are chemically stable. They are acid, alkali, and corrosion resistant! They are also moisture-proof, heat-insulating, sound-insulating, flame-retardant, lightweight, and low-density. “Qiquan” high-density oxidized polyethylene wax products contain a certain amount of carbonyl and hydroxyl groups, which can help customers achieve excellent plasticization control and metal release. Their high melting point and low viscosity promote good resin fluidity, effectively helping product processing and demolding, achieving a smooth surface and high gloss, providing a wider processing window, and acting as an internal and external lubricant.

鲁公网安备 37030502000442号

鲁公网安备 37030502000442号